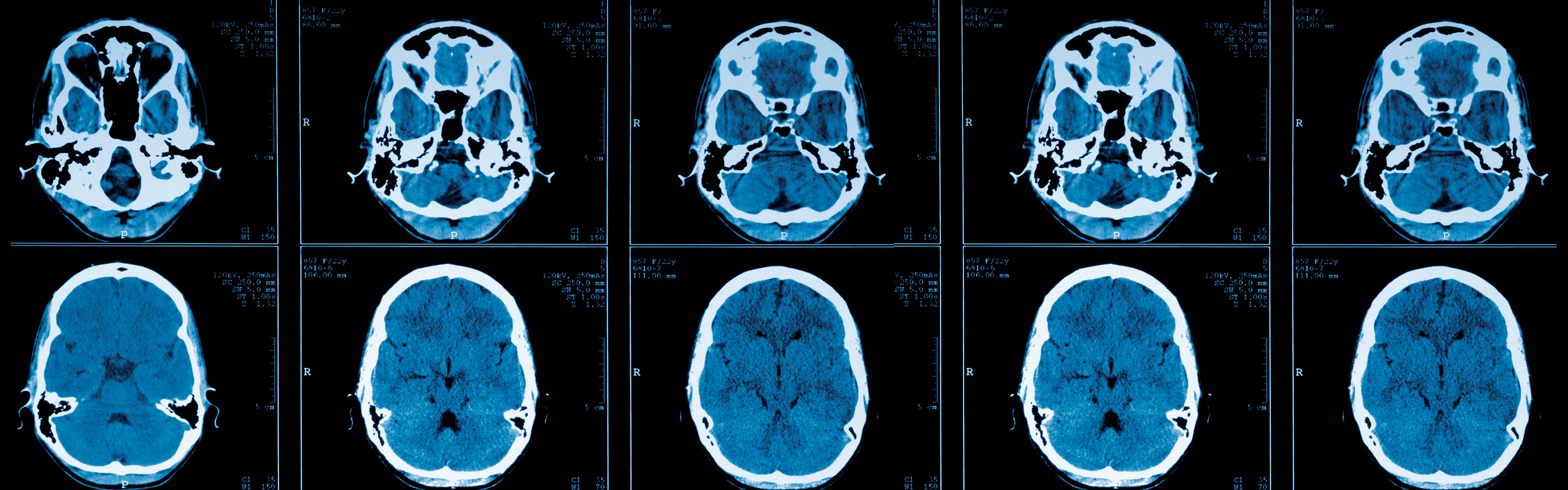

Medicine.

Cooling systems for medical storage, laboratory and analysis. And especially for applications in imaging diagnostics.

MRI diagnostic with MC-Chiller.

Radiological and nuclear medicine center, Lauf a. Pegnitz, Germany.

Challenge / Generating strong magnetic fields requires particularly powerful solenoids, known as superconducting solenoids, which must be cooled to minus 269°C. Precision work of this nature requires an enormous amount of technology, with purchase costs ranging between 1.5 and 2 million euros – an investment that has to pay for itself as quickly as possible.

Solution / The Riedel Kooling MC chiller with an additional free cooler module on the roof ensures an efficient and reliable cooling supply. The goal is to avoid temperature fluctuations. At outside temperatures below 6°C, the free cooler uses the surrounding air as an additional source of cooling capacity. This results in lower power consumption. Total electricity costs per year have seen a reduction of as much as 5000 euros, and CO2 emissions have fallen too.

Highend cooling for MRI systems.

Johnson Controls Building Solutions, Prague, Czechia.

Yet high-tech devices, such as magnetic resonance imaging systems, only work reliably if they have safe, precise cooling. Furthermore, these cooling units have to operate particularly quietly so that they do not disturb clinical operations.

Challenge / Not long ago, the coolers in the MRI systems came from different manufacturers. They were installed by different local service providers and another company dealt with the service aspect. The components were not coordinated with one another and the wheel had to be re-invented for every system. This meant that customers experienced frequent downtimes, repairs and stress.

Solution / They made contact with Riedel Kooling in Kulmbach via Johnson Controls Building Solutions in Prague because of the complex situation that they faced. Riedel Kooling had the right high-end cooling system, perfectly developed for the customer’s specific applications. All components are perfectly coordinated with one another.

Cooling for medical technology.

Radiology at Raschplatz, Hanover, Germany.

Challenge / The key components of a superconducting MRI system must be precisely cooled, as this is essential to obtaining the sharp MRI images that are needed in this application. Keeping the entire cooling chain running reliably is always the top priority. Quiet operation is another important factor.

Solution / The planning engineers opted for a chiller from the MC series. Chillers of this type operate extremely quietly and fulfil the requirements for modern cooling solutions with refrigeration capacities between 40 and 75 kW. Various options create the possibility of devices in the style of a modular system. Remote control panels facilitate system control, energy-saving modules lower operating costs and system safety is increased with the installation of an emergency water supply module or filter kit.

Industry.

Cooling systems for industry, laser & high-tech applications.

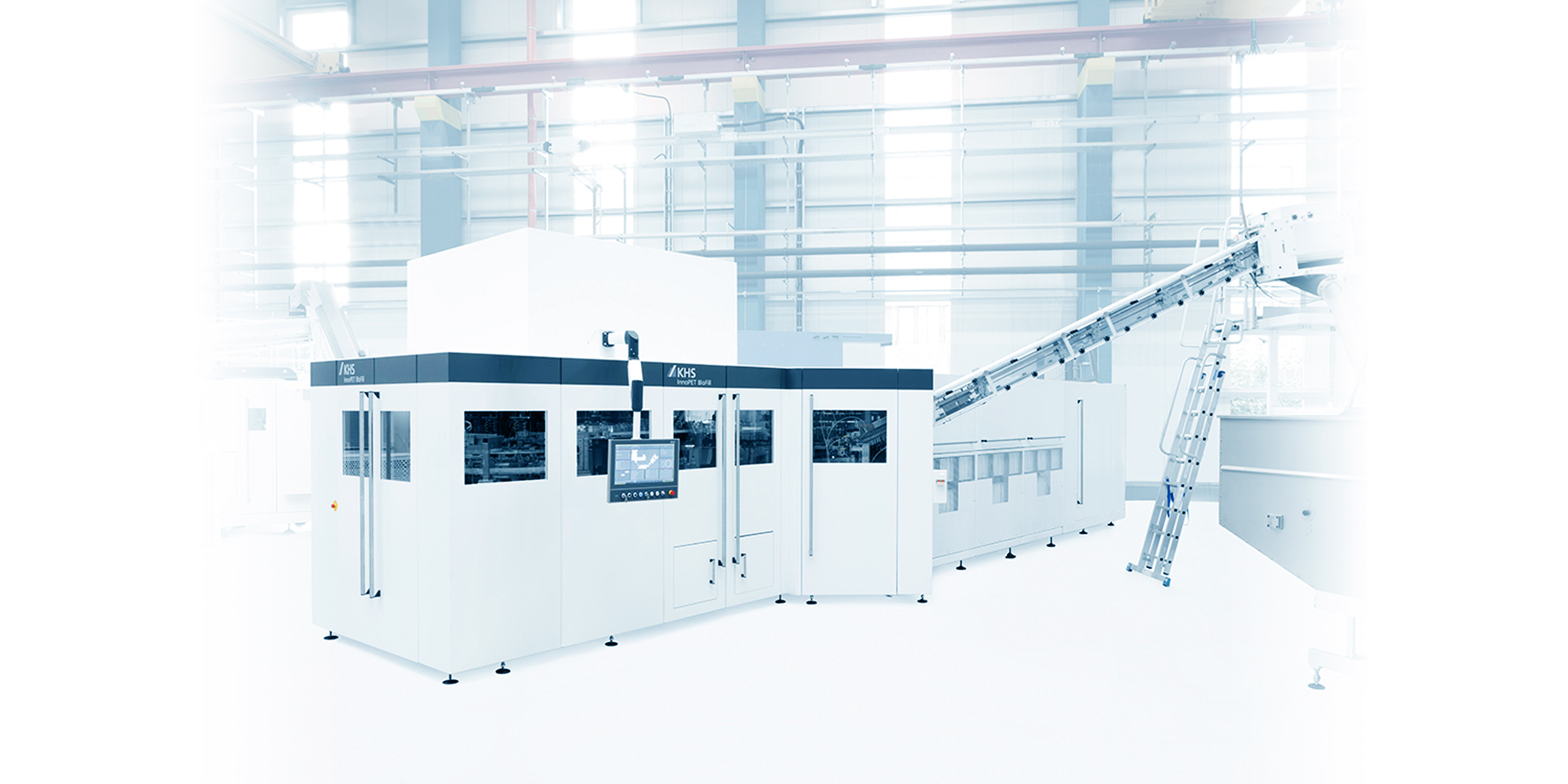

Cleverly packed. Efficient cooling solutions for the packaging industry.

How do cat litter bags actually become leakproof?

Or: How modern bag closing machines are cooled.

For over 60 years, Meypack in Nottuln-Appelhülsen has been an expert for solutions in the fields of carton packaging technology, film packaging technology, palletizing/depalletizing technology and bag closing technology. In a bag closing machine (also known as a continuous belt sealing machine), plastic bags are sealed or internally coated paper bags are sealed - in our case paper bags for cat litter.

The paper bags are provided with a hot-melt adhesive edge in the upper area, which is first melted and then pressed and finally cooled under pressure. The adhesive is cooled using water-cooled cooling jaws, which are supplied with cold water from an SC series chiller. The water temperature is set to the required temperature value. The chiller is supplied ready for operation. The compact chiller can be easily attached to the machine to save space. And commissioning is quick and easy.

Top rating for quality & service.

ThermoTEC, Weilburg, Germany.

Solution / ThermoTEC has been a customer of Riedel Kooling since 2011. Chillers from the PC series and heat exchangers ensure high-precision cooling of climate test chambers, thermal shock test chambers, HAST systems, as well as other devices and systems for environmental simulation. Climate chambers and plant growth chambers for botanical testing, test chambers and chambers for stability testing on medication in the pharmaceuticals industry, as well as test chambers for battery tests, are cooled reliably and continuously.

5 out of 5 stars / "The quality of the cold water set with heat exchanger is reflected in the excellent reliability. We have had no downtimes to date since the installation. The system works perfectly even in high outside temperatures. The high level of expertise of the employees is also clear during enquiries regarding new purchases", emphasizes Arnd Böcher, authorized representative at ThermoTEC, indicating his level of satisfaction with Riedel Kooling with 5 out of 5 stars.

Precise cooling in plastics processing.

KHS Corpoplast, Hamburg, Germany.

Challenge / The Blowmax blow-moulding machines consist of 13 performance types. In the past, up to 39 different chillers were available for these machines depending on the ambient temperature. The partners joined forces and started looking for ways to reduce the variety, while also increasing the competitive advantage through standardisation.

Solution / One chiller type for a defined pool of blow-moulding machines. Each chiller had to cover a specific refrigeration capacity depending on the volume flow and pump pressure, with an ambient tempera-ture of 45 °C. Based on this requirement, Riedel Kooling developed four chiller platforms with a power of 25, 40, 60 or 90 kW. The new platform solution has positive impacts for both sides. For KHS, the technical, commercial and logistical work is reduced. For Riedel Kooling, much less material has to be held in stock, the number of identical parts is increased and KHS orders defined, easily plannable quantities.

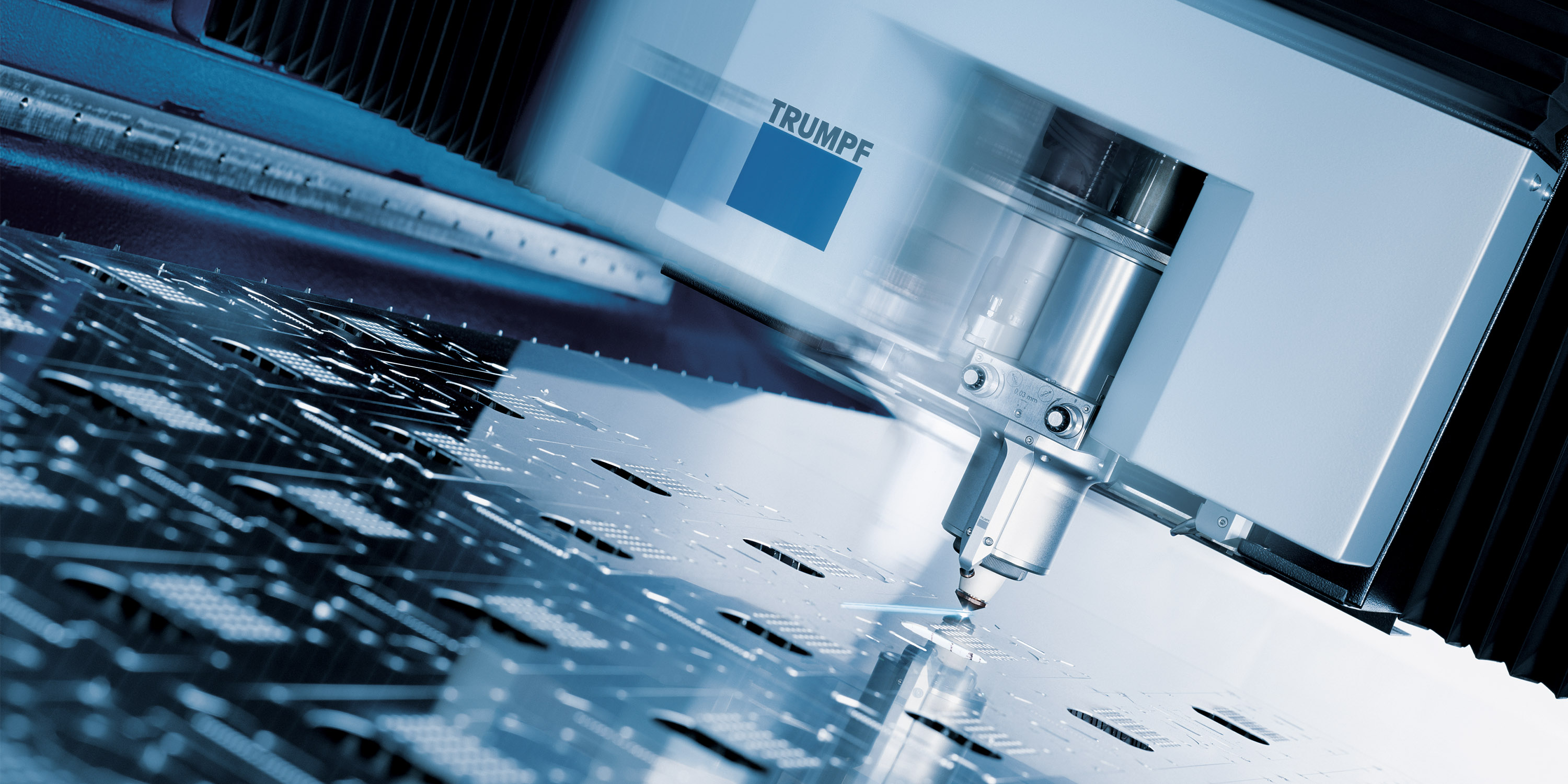

Networked cooling for TRUMPF.

TRUMPF, Stuttgart, Germany.

Challenge / High-performance lasers and machine tools autonomously perform system analyses and sound the alarm at an early stage before problems occur. The individual modules and components have the capacity to think, helping to optimise the production process in a fully automated and intelligent manner. Efforts to network the machines fully are expected to yield a productivity gain of 30 percent within five years.

Solution / In order for networking to be productive, it needs the input of reliable partners. Machine tools (and integrated lasers in particular) produce heat and require continuous and precise cooling to run smoothly. For more than 30 years, Riedel Kooling has been supplying global market leader TRUMPF with powerful and reliable cooling units. In the future, it will be possible to connect the Riedel cooling units to all the other relevant components in the network in which they operate. This means that it will also be possible to integrate the units into TRUMPF remote services, enabling remote access and all the advantages that this brings with it.

A third of energy consumption is saved.

Automotive Supplier, Germany.

Plasma temperatures of around 600°C occur at the plant of an automotive supplier when engine components are being coated with a special PVD film. This is what creates the extremely high-quality components on which many large companies rely.

Challenge / In recent years, production has grown significantly due to increasing demand – and with it the need for cooling. The existing systems were still working, but used vast amounts of energy.

Solution / The correct temperature is now always guaranteed by two PC2241 (process cooling) and one PC2001 (air-conditioning) units from Riedel Kooling, each of which is combined with water-bearing free coolers. Process cooling and air-conditioning have been separated as they require different flow temperatures. The new cooling system has been moved outside and is controlled centrally via a control centre.

Using heat and cold with true efficiency.

Silberhorn, near Regensburg, Germany.

Challenge / To implement an energy-saving and sustainable concept for the production site in Brunn (sheet metal production). The project focused on achieving a marked reduction in CO2 emissions and a noticeable fall in energy costs, while at the same time providing precise, continuous cooling of the production process.

Solution / The Riedel Kooling energy-saving solution has been in operation since November 2017. It not only offers 100 % redundancy in the cooling system, but also covers the entire heat consumption via the waste heat generated. Perfectly coordinated individual devices: Each year the Riedel Kooling hydraulic unit, along with its integration into the central building management system, saves around 360,000 kWh of electricity and 364 tonnes of CO2 (compared to a patchwork solution without waste heat recovery).

European Organisation for Astronomical Research (ESO).

Paranal Observatorium, Chile.

In the middle of the Atacama Desert in northern Chile, four 22-watt lasers generate artificial guide stars. The purpose of these is to compensate for optical blurs caused by the Earth’s atmosphere and ensure that the telescope receives sharp images as a result.

Challenge / The laser sources need a compact, low-vibration cooling system that is neutral to external temperatures, requires as little maintenance as possible, and is equipped with leakage monitoring in case of an emergency. In this part of South America, earthquake and frost protection is also essential.

Solution / A cooling system that is so safe and low-maintenance that it can run unattended for two years. This is a huge advantage in an area far away from main traffic routes – and is made possible by factors including a special insulating material that does not swell, even at over 2,500 metres.